How to Source Streptomycin injectable for Pharmaceutical Formulation

Streptomycin injectable (Injectable (IV/IM), 1 g/2 mL, 2 g/2 mL) is classified under Antibiotics. It is therapeutically aligned with reference brands such as Generic formulations marketed under different names. This guide highlights key sourcing factors buyers should consider when procuring high-quality Streptomycin injectable for formulation, R&D, or bulk manufacturing.

Product Overview:

Streptomycin inhibits bacterial protein synthesis by binding to the 30S ribosomal subunit, causing improper protein formation and bacterial death. It is effective against tuberculosis and severe bacterial infections. Benefits include rapid bactericidal activity, high efficacy against multidrug-resistant bacteria, and use in critical care settings when administered properly.

Streptomycin injectable is approved in the EU and US for treating tuberculosis and serious bacterial...

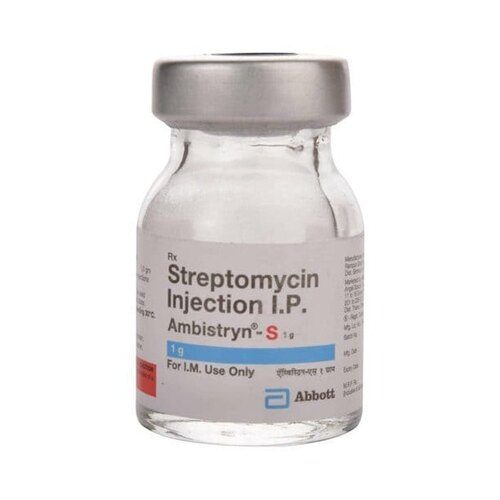

Streptomycin injectable API – ideal for compliant pharmaceutical formulation.

Streptomycin injectable API – ideal for compliant pharmaceutical formulation.

Quick Insight: Over 60% of formulation delays are linked to poor API sourcing. A well-planned sourcing strategy can reduce risk and accelerate market entry.

1. Regulatory Compliance & Documentation

Ensure suppliers provide:

- ✔ Valid DMF (Drug Master File)

- ✔ COA (Certificate of Analysis) for each batch

- ✔ GMP, ISO, or ICH Q7 compliance certificates

2. Purity, Grade & Specification Matching

Streptomycin injectable must meet exact grade and purity for your dosage form:

- ✔ USP / EP / JP grade verification

- ✔ Particle size distribution check

- ✔ Residual solvent and heavy metal limits

3. Supplier Reliability & Audit History

- ✔ Positive past audit reports

- ✔ Pharma client references

- ✔ Years of proven API manufacturing experience

4. Commercial Terms: Pricing, MOQ & Flexibility

- ✔ Transparent pricing

- ✔ Pilot batch MOQ flexibility

- ✔ Volume-based discounts

5. Lead Time, Inventory & Logistics

Typical lead time for Streptomycin injectable is 4–6 weeks.

- ✔ Emergency dispatch options

- ✔ Regional warehousing

- ✔ Special storage if needed

6. Formulation Support

- ✔ Technical datasheets

- ✔ Sample availability

- ✔ Stability study support

Pro Tip: Engage supplier formulation experts early — it can improve bioavailability and cut development time.

Conclusion

Sourcing Streptomycin injectable is more than procurement—it’s a strategic partnership. With its injectable (iv/im) form and 1 g/2 mL, 2 g/2 mL specification, choosing a compliant supplier ensures consistent quality and regulatory approval. Prioritize documentation, verify compatibility, and build relationships with transparent, reliable suppliers to secure long-term success.

Next Step: Get expert assistance in sourcing Streptomycin injectable.

Request a Quote

Frequently Asked Questions For Sourcing of Streptomycin injectable

What is the typical lead time for Streptomycin injectable?

Lead times range from 4–6 weeks depending on supplier and region.

Is Streptomycin injectable available in multiple grades?

Yes — common grades include USP, EP, and JP. Verify grade suitability for your dosage form before purchase.

Does Streptomycin injectable require special storage?

It should be stored in a cool, dry place away from direct sunlight.

Is a Drug Master File (DMF) available for Streptomycin injectable?

Yes, a DMF is available for regulated markets upon request. It includes detailed quality, manufacturing, and stability data.

Can I request samples or a pilot batch of Streptomycin injectable?

Yes — pilot batches or samples can be arranged for R&D, stability studies, or formulation trials. MOQ may vary based on region and regulatory scope.

What compliance certificates are available for Streptomycin injectable?

Available documentation may include GMP, ISO 9001, ISO 14001, and ICH Q7 certificates, along with CoA, TDS, and stability data.

Is Streptomycin injectable suitable for regulated markets like US/EU?

Yes — compliant with EU/US/WHO GMP standards and available with regulatory support documentation for filings.

Can Streptomycin injectable be used in fixed-dose combinations?

Yes — many formulations support inclusion in FDCs. Compatibility studies and formulation consultation are available on request.

This website uses cookies to ensure you get the best experience. By using our site, you agree to our

Privacy Policy.